|

Product Details:

|

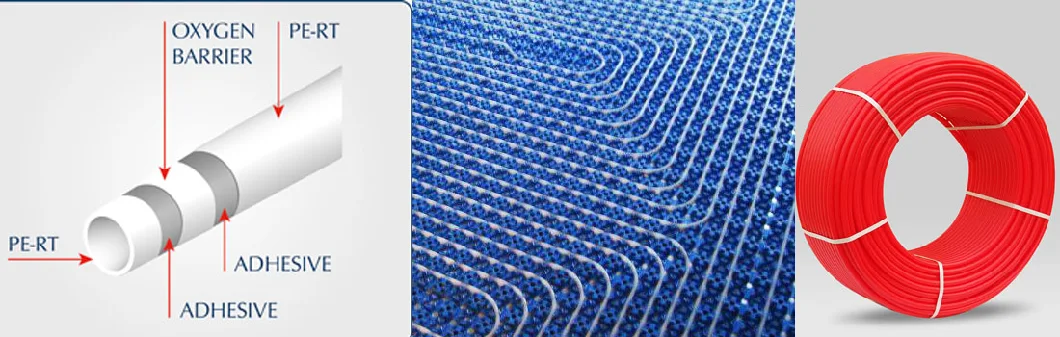

| Product Name: | Five Layers Pert EVOH Pipe Production Line | Pipe Layers: | 3 Or 5 Layer |

|---|---|---|---|

| Producing Speed: | 60m/min | Pipe Size: | 16-32mm |

| Control: | Siemens PLC Control System | Electric Component: | Schineider |

| Machine Dimension: | 45m*3.5m*3m | ||

| High Light: | EVOH Floor Heating Pipe Production Line,16mm EVOH Pipe Extrusion Line |

||

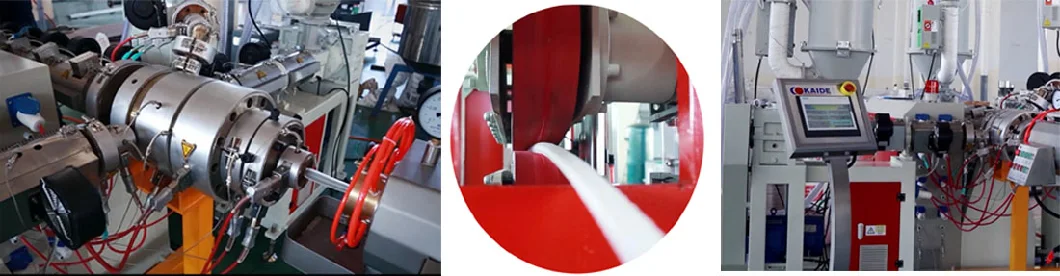

EVOH PERTPipe Making Machine,The composite EVOH PERT pipe production line adopts advanced extrusion technology with several extruders specially designed for Pe-xb pipe and co-extrusion die head mold, which makes the composite pipe bond firmly with precise size. Also with special extruder designed according to the property of EVOH resin. It is suitable for stable extrusion of high melt pressure of oxygen barrier resin.

EVOH PERTPipe Making Machine,The composite EVOH PERT pipe production line adopts advanced extrusion technology with several extruders specially designed for Pe-xb pipe and co-extrusion die head mold, which makes the composite pipe bond firmly with precise size. Also with special extruder designed according to the property of EVOH resin. It is suitable for stable extrusion of high melt pressure of oxygen barrier resin.

| Line Model | Screw Diameter | L/D | Production Scope | Production Speed |

| SJ-65 | Ф65/30mm | 33:01:00 | Ф16-32mm | 60m/min |

| SJ-65 | Ф65/30mm | 33:01:00 | Ф16-63mm | 40m/min |

Contact Person: Ms. Forina

Tel: 86-15169542387

Fax: 86-536-8650536