|

Product Details:

|

| Name: | HDPE Silicone Core Tube Extrusion Machine | Control System: | Siemens PLC Control |

|---|---|---|---|

| Line Speed: | 80m/min 120m/min | Electrics Components: | Schneider Brand |

| Raw Materials: | HDPE/Silicone Core | Pipe Application: | Tel Communication Optical Fiber |

| High Light: | HDPE Core Tube Making Machine,Silicone Core Tube Making Machine,60m/min Tube Making Machine |

||

| Line Model | Screw Diameter | L/D | Micro-duct Size | Production Speed |

| KDGX-75 | Ф75mm/50mm | 36/30:1 | 7-14mm | 80m/min |

| KDGX-60 | Ф60/mm/45mm | 36/30:1 | 7-14mm | 50m/min |

| KDGX-65 | Ф65mm/45mm | 33/30:1 | 7-14mm | 20m/min |

| No. | Duct Size (OD/ID) mm | Outer Diameter mm | Inner Dimaeter mm | Total Thickness mm |

| 1 | 7/3.5 | 7 | 3.5 | 1.75 |

| 2 | 10/6 | 10 | 6 | 2 |

| 3 | 12/8 | 12 | 8 | 2 |

| 4 | 14/10 | 14 | 10 | 2 |

| 5 | 16/12 | 16 | 12 | 2 |

| 6 | 20/16 | 20 | 16 | 2 |

3) Special designed vacuum tank for small size micor-duct making, with more stable vacuum degree. High quality stainless steel SS304 is used, and with special surface treatment is done to prevent the rust and corrosion.

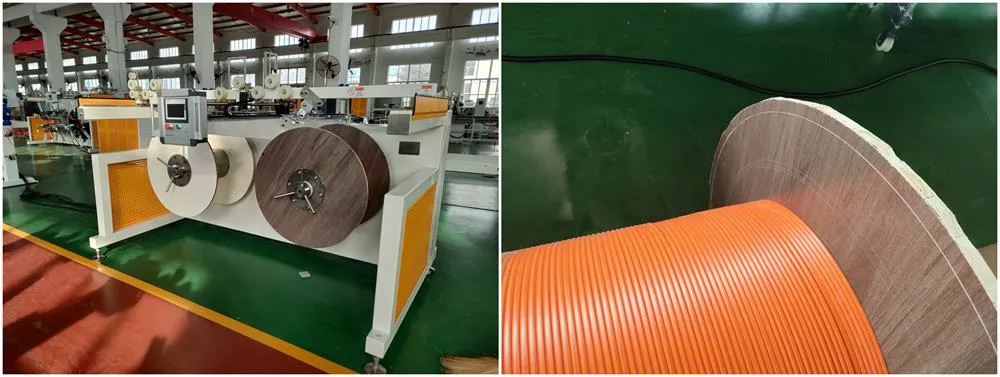

3) Special designed vacuum tank for small size micor-duct making, with more stable vacuum degree. High quality stainless steel SS304 is used, and with special surface treatment is done to prevent the rust and corrosion. 5) New generation pipe winding machine, with servo type traversing device, to coil the pipe at high speed and also nice arrangement.

5) New generation pipe winding machine, with servo type traversing device, to coil the pipe at high speed and also nice arrangement.

Company View

Kaide Plastics Machinery Co.,ltd has more than 20 years' experience of plastics pipe extrusion machinery, especially for high speed pipe production line and composite pipe production line.

Our main products are:

Flat drip irrigation tape line,Round Drip Irrigation pipe machine

PPR/PERT/HDPE pipe line,Glassfiber PPR Pipe Line,PPR-AL-PPR pipe line,PEX-AL-PEX pipe machine,PERT-AL-PERT pipe machine,Mulilayer Al-plastic pipe production line,Multi-layer EVOH/PERT/PEXA/PEXB pipe line,PB pipe production line,PPR pipe machine, Medical catheter line,etc .

(1) The machinery have been exported to many countries, such as: Russia, USA, Korea, Algeria, Egypt, Iran, Japan, Kyrghyzstan, Cyprus, Morocco, Ukraine, Mexico, Estonia, Saudi arabia, Uzbekistan, etc,which has gained high reputation from the customers.

(2)Professional R&D team,which are continuously concentrating on optimizing of our technology to keep the leading position. Several technologies have obtained nationalinvention patent & utility model patent;The Whole process of machine manufacturing is under good quality control.

(3)From raw material purchasing, to components manufacturing, thento test running of the line, each process we have strict quality requst, to ensure that a high quality product will be delivered to the customer; We cooperate with well-known enterprises for some mechanical parts, such as: ABB, Siemens, Schneider,Autonics, SMC,Delta,ORMON,Eurotherm,PAKER, etc.

(4)We are located in Weifang, Shangdong Province, near to Qingdao city,warmly welcome to visit our factory, here is two hours away from Shanghai, one hours away from Beijing, three hours away from Guangzhou.

For more information, please feel free to contact us !

Contact Person: Ms. Forina

Tel: 86-15169542387

Fax: 86-536-8650536